OEM tailor design

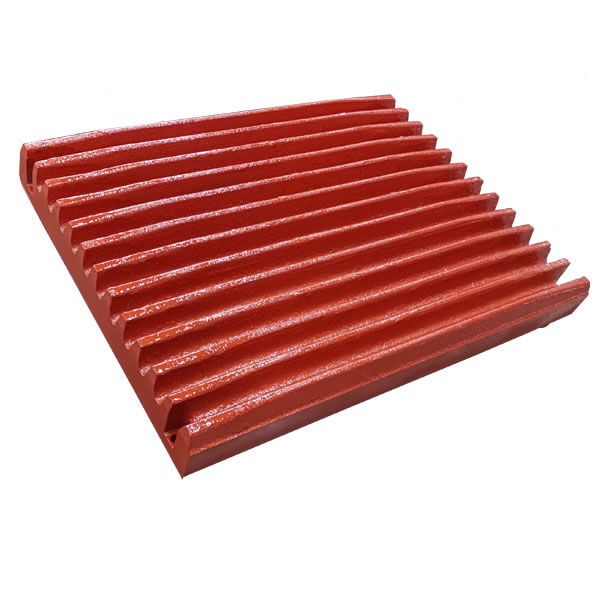

Product name: Steel Ball

Production process: Casting

Applicable machines: Ball mill

Material types: High manganese steel, high manganese steel + surfacing, high chromium cast iron, alloy steel, etc.

Applicable industries: mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

Balls in ball mills have different milling effects on materials depending on size, weight and material. Different sizes of steel balls can perform better milling in a certain proportion in the same abrasive silo.

Our company provides professional matching service for steel ball, and at the same time, we recommend the steel ball material that is most suitable for your working conditions and materials.

Chemical component

Grade | Chemical component % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| вүҘ10 | вүӨ1.2 | вүӨ2.0 | 14~18 | вүӨ3.0 | вүӨ2.5 | вүӨ1.2 | вүӨ0.06 | вүӨ0.10 | |

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

| Casting condition | Hardened or hardened stress relief treatment Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| вүҘ46 | вүҘ450 | вүҘ58 | вүҘ650 | вүӨ41 | 400 | |

1пјҡThere are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used | ||||||

Chemical component

Grade | Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| 3.0~10 | вүӨ1.2 | вүӨ2.0 | 14~18 | вүӨ3.0 | вүӨ2.5 | вүӨ1.2 | вүӨ0.06 | вүӨ0.10 | |

1пјҡAllowed to add microscale V,Ti,Nb,B and Re etc. | |||||||||

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

As-cast or as-cast stress Casting condition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| вүҘ46 | вүҘ450 | вүҘ58 | вүҘ650 | вүӨ41 | 400 | |

| 1пјҡThere are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend usedгҖӮ 2пјҡThe hardness in the 40%deepness of casting section should be lower than 92% hardness of surface. | ||||||

Chemical component

Grade | Chemical component % | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| 1.5~3.0 | вүӨ1.2 | вүӨ2.0 | 14~18 | вүӨ3.0 | вүӨ2.5 | вүӨ1.2 | вүӨ0.06 | вүӨ0.10 | |

| 1пјҡAllowed to add microscale V,Ti,Nb,B and Re etc. 2пјҡWe will choose grade and specific component according to blow barsвҖҷ weight ,thickness and sizes | |||||||||

Mechanical Property

| Grade | Surface Hardness | |||||

|---|---|---|---|---|---|---|

| As-cast or as-cast stress Castingcondition | Harded condition | Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | вүҘ46 | вүҘ450 | вүҘ58 | вүҘ650 | вүӨ41 | 400 |