OEM tailor design

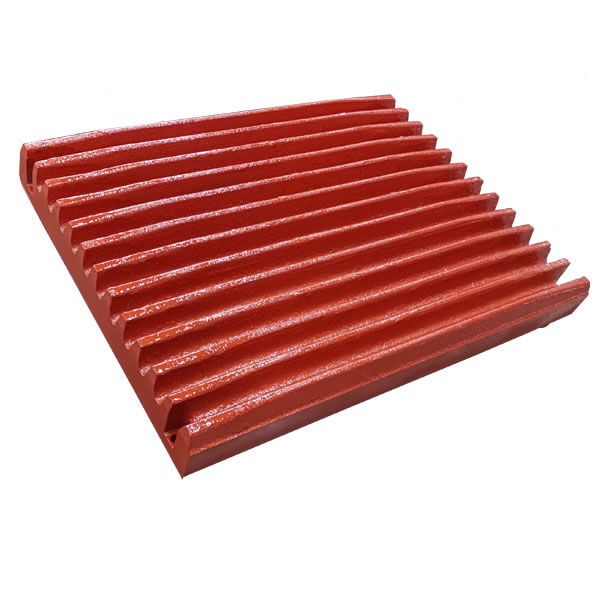

Product name: Vertical mill roller,Grinding roller

Production process: Casting

Applicable machines: Vertical mill

Material types: high chromium cast iron, Medium alloy steel etc.

Applicable industries: Mining, cement plants, coal, steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

The most material of grinding roller is high Chrome,add the surfacing welding can extend lifetime and reduce costs and improve efficiency.Surfacing welding include Welding wire hard facing and Alloy studs inlaid surfacing welding.

Welding wire surfacing grinding roller improves the wear resistance and service life by surfacing wear-resistant welding wire on the surface of the roller body.

The Alloy studs inlaid surfacing welding vertical grinding roller is designed according to the working conditions and the wear resistance curve of the product. In the wear area, the powder metallurgy technology and surfacing technology are combined, and the special welding materials are used to form the inlay welding structure and metallurgical combination, improve the wear resistance and service life of the product, and achieve the regenerative repair to improve the service life of the product.

High chromium iron

Feature:

We use proper alloying and and related technological measures to make the blow bars’ surface hardness reaches more than 58HRC , during the process of wearing will maintain high hardness and high wear resistance.

Technology process

In blow bars’ working part we use the technique of directional solidification to make Cr7C3 type carbide is perpendicular to the part.The macro-hardness and micro hardness of carbide can be improved without reducing thoghness.

Application

Suitable for making wearable spare parts with lower impact load and simpler shape.

Chemical component

Grade | Chemical component% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Ni | Cu | S | P | |

| BTMCr15 | 2.0~3.3 | ≤1.2 | ≤2.0 | 14~18 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr20 | 2.0~3.3 | ≤1.2 | ≤2.0 | 18~23 | ≤3.0 | ≤2.5 | ≤1.2 | ≤0.06 | ≤0.10 |

| BTMCr26 | 2.0~3.3 | ≤1.2 | ≤2.0 | 23~30 | ≤3.0 | ≤2.5 | ≤2.0 | ≤0.06 | ≤0.10 |

| 1пјҡAllowed to add microscale V,Ti,Nb,B and Re etc. 2пјҡWe will choose grade and specific component according to blow bars’ weight ,thickness and sizes | |||||||||

Mechanical Property

| зүҢеҸ· Grade | иЎЁйқўзЎ¬еәҰ Surface Hardness | |||||

|---|---|---|---|---|---|---|

| й“ёжҖҒжҲ–й“ёжҖҒеҺ»еә”еҠӣ Casting condition | зЎ¬еҢ–жҖҒжҲ–зЎ¬еҢ–жҖҒеҺ»еә”еҠӣеӨ„зҗҶ Harded condition | иҪҜеҢ–йҖҖзҒ«жҖҒ Softening annealing condition | ||||

| HRC | HB | HRC | HB | HRC | HB | |

| BTMCr15 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr20 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

| BTMCr26 | ≥46 | ≥450 | ≥58 | ≥650 | ≥41 | 400 |

1пјҡThere are no exact corresponing value between rockwell hardness(HRC) and brine hardness(HB),so ,this two kind of hardness value can be inspend used гҖӮ | ||||||

Medium alloy steel

Feature

The alloy structure cast steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloy elements on the basis of ordinary carbon steel.

Process technology

According to the different elements added, with appropriate smelting and heat treatment process to obtain high strength, high toughness, high wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic and other related special properties.

Scope of application

It is suitable for producing the wear-resisting spare parts with good mechanical strength and good toughness that are required for various working conditions, and the main steel structure castings with the required dynamic load.

Chemical component

Grade | Chemical component % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | S | P | Ai | |||

| ZG42CrMo | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.80-1.10 | 0.15-0.25 | <0.04 | <0.035 | - | ||

| ZG35CrMo | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | - | ||

| ZG38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | 1.35~1.65 | 0.15~0.25 | ≤0.04 | ≤0.04 | 0.7~1.1 | ||

| ZG40Cr | 0.37~0.45 | 0.17~0.37 | 0.5~0.8 | 0.8~1.1 | - | - | - | - | ||

| ZG30Mn2SiCrMo | 0.25~0.35 | 0.40~0.80 | 1.20~1.60 | 1.35~1.65 | 0.2~0.5 | ≤0.04 | ≤0.04 | - | ||

Mechanical Property

| Grade | tensile strengthпјҲMpaпјү | yield strength пјҲMpaпјү | Elongation at cross sectionпјҲ%пјү | reduction of crosssection areaпјҲ%пјү | Shock absorption energyпјҲKV2/Jпјү |

|---|---|---|---|---|---|

| ZG42CrMo | ≥1080 | ≥930 | ≥12 | ≥20 | ≥24 |

| ZG35CrMo | ≥985 | ≥835 | ≥12 | ≥20 | ≥24 |

| ZG38CrMoAl | ≥980 | ≥835 | ≥14 | ≥20 | ≥24 |

| ZG40Cr | ≥980 | ≥785 | ≥9 | ≥20 | ≥24 |

| ZG30Mn2SiCrMo | ≥1500 | ≥1300 | ≥3 | - | ≥24 |