OEM tailor design

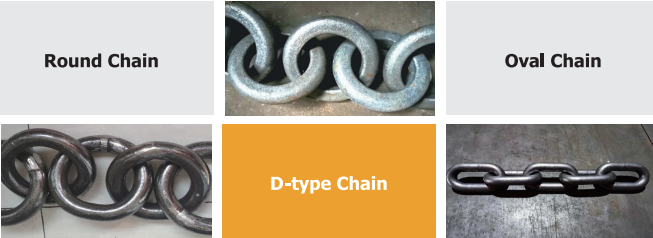

Product name: D-type chains/Heat-resistant steel chains/Round chains/oval chain/Rotary kiln chain/D-type shackles/Bow-shaped shackle

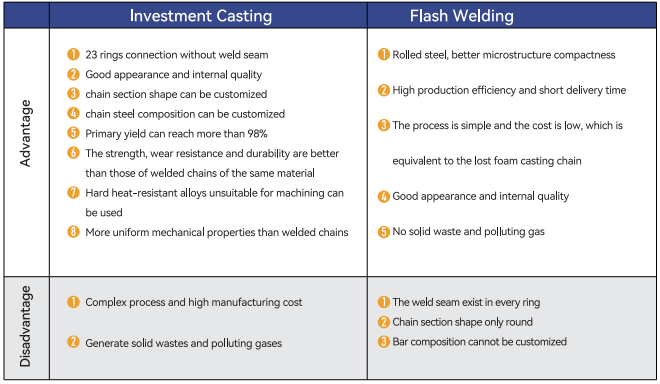

Production process: Casting,Investment casting process,Forged

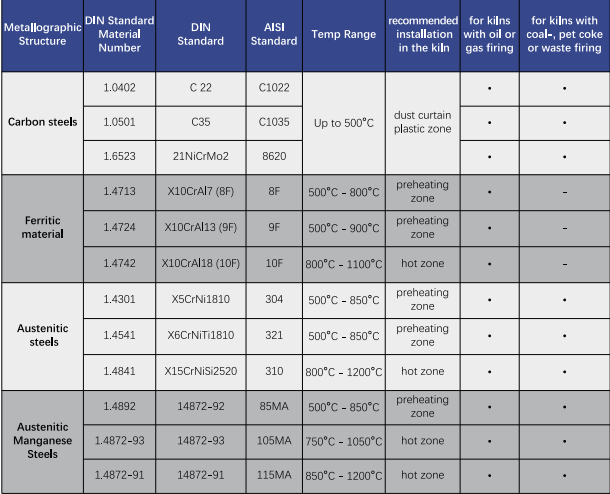

Material types:115MA,Low-alloy heat-resistant steel, low-chromium-nickel oxidation-resistant steel,etc.

Applicable industries: Cement, metallurgy, chemical industry, architecture,steel,Papermaking, metallurgy, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(cnwearparts@lyzhili.com), because we are a customized factory for heat-resistant steel castings.

D-type shackles include general lifting shackles, marine shackles and ordinary shackles. They are heavy and large in size, and are generally not installed in places where they are not often disassembled. When choosing a shackle, you should pay attention to the safety factor, which is generally 4 times, 6 times and 8 times.

The main shapes of shackles are D-type and bow-shaped, and customized production of other shapes and materials is supported.

It adopts a manufacturing method combining alloy steel, die forging and free forging, and is widely used in various industries such as electricity, metallurgy, petroleum, machinery, railways, chemicals, ports, mining, and construction. However, it should be noted that the use of the shackle must not exceed the specified safety load.The metal surface is coated with zinc, nickel, cadmium, composite plating and other coatings to prevent corrosion.

D-type shackle parameters:

Rated load T | A mm | B(Ф) mm | C mm | D(Ф) mm | E mm | F mm | G mm |

| 3 | 42 | 30 | 27 | 60 | 150 | 96 | |

| 5 | 58 | 38 | 34 | 76 | 195 | 126 | 104 |

| 8 | 61 | 40 | 35.5 | 96 | 212 | 133 | 109 |

| 10 | 66 | 45 | 39 | 100 | 235 | 144 | 144 |

| 15 | 70 | 50 | 46 | 89 | 274 | 162 | 159 |

| 20 | 79 | 55 | 51 | 112 | 308 | 181 | 174 |

| 25 | 88 | 60 | 61 | 122 | 329 | 210 | 177 |

| 32 | 100 | 70 | 66 | 138 | 395 | 232 | 215 |

| 40 | 110 | 80 | 75 | 158 | 440 | 260 | 246 |

| 50 | 130 | 90 | 76 | 158 | 468 | 282 | 268 |

| 60 | 130 | 95 | 80 | 178 | 290 | ||

| 80 | 124 | 100 | 92 | 178 | 520 | 308 | 289 |

Industrial D-shaped rings are made of special high-strength forged steel combined with heat treatment and welding technology, and are mainly used in coal mines, ships, cement, construction and other industries.

Cement kiln chains mainly include: round kiln chain, oval kiln chain, HEAT-X kiln chain,etc.

Advantages:

1.Proprietary alloy can extend the life of the chain link;

2.Stable heat resistance, good heat transfer effect;

3.Various materials to meet customer needs.

chain manufacturing process comparison

comparison of chain steel composition