Global Sales OEM tailor design

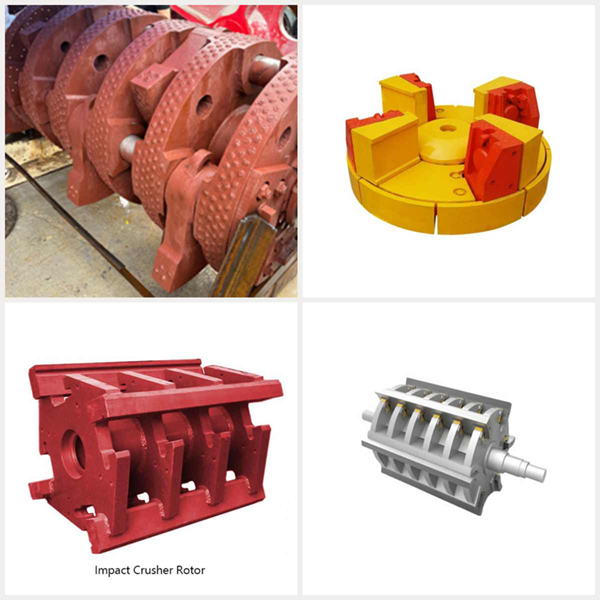

Product name: Hammer Crusher Rotor/Hammer disc/Hammer shaft/rotor disc/Impact Crusher Rotor/VSI Crusher Rotor/Rotor Assembly

Production process: Casting

Applicable machines: Clinker crusher,Impact Crusher, raw material crusher, auxiliary material crusher, metal crusher,VSI crusher, etc.

Applicable industries: Cement, stone, coal, steel, metal recycling, power, metal mines,etc.

Material types: High manganese steel(Mn13Cr2/Mn18Cr2), Super high manganese steel insert alloy bars, high manganese steel + hard facing layer,High strength plate Q690, Q550,Q345,etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(cnwearparts@lyzhili.com), because we are a customized factory for crusher spare parts.

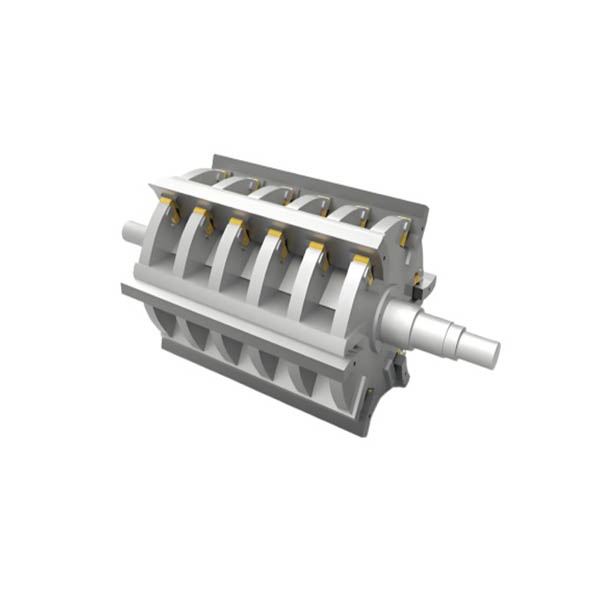

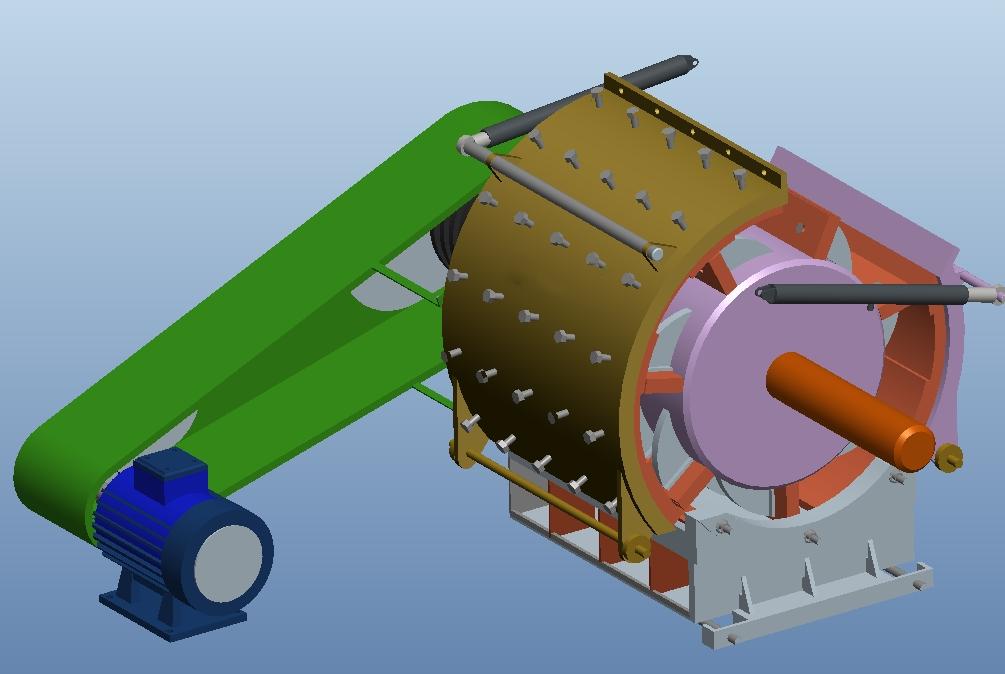

The crusher rotor is the heart of the hammer crusher.The hammer crusher rotor is composed of a main shaft, a hammer frame, and hammer heads. The size of the rotor varies according to the specifications of different hammer crushers. Zhili New Materials using advanced finite element analysis technology to effectively improve the design of the crusher rotor and extend the service life of the rotor.

Hammer Crusher Rotor :High manganese insert alloy bars

Hammer Crusher Rotor :high manganese steel + surfacing

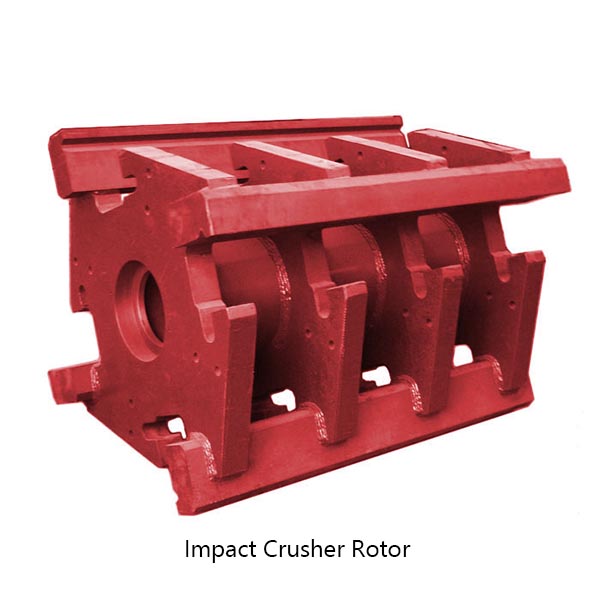

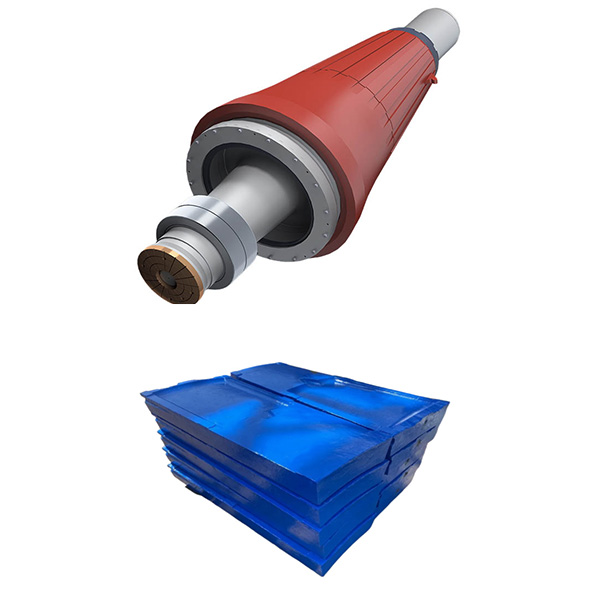

The rotor assembly of the impact crusher equipment includes the main shaft, drum, bearings, blow bar, baffle, protective plate, pressing block, guard plate, baffle, and bearing seat.

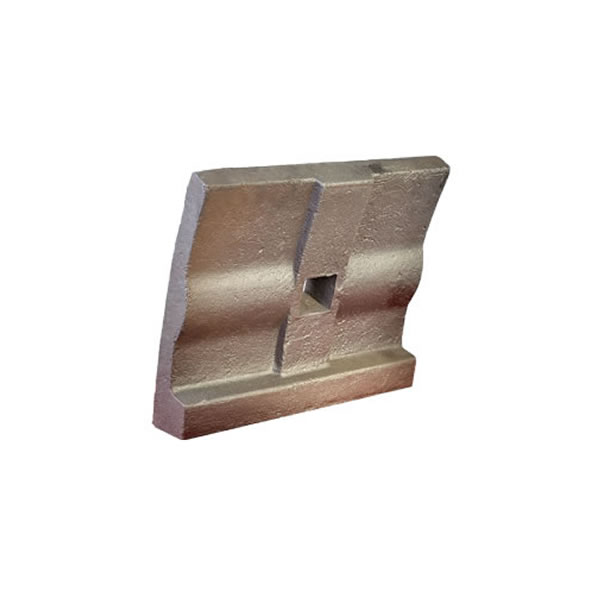

The blow bar material of the impact crusher equipment is high manganese steel,ceramic metal composite,high manganese steel insert alloy bars,etc. The optimized crescent-shaped blow bar can ensure vertical impact of materials, with strong impact force and high crushing efficiency. Its impact surface is larger than that of a linear blow bar, making it more durable.

The blow bar is fixed on the rotor by wedge blocks, and the contact surface between the wedge block and the belly plate is trapezoidal. This fixing method ensures that the faster the rotor speed, the more firmly the blow bar is fixed, and the more reliable and convenient it is to disassemble and replace.

The bearing seat of the impact crusher equipment is made of integral cast steel material and is fixed on the frame with bolts. The combination of the integral bearing seat and the bearing is more compact, which can prevent the bearing from jumping.

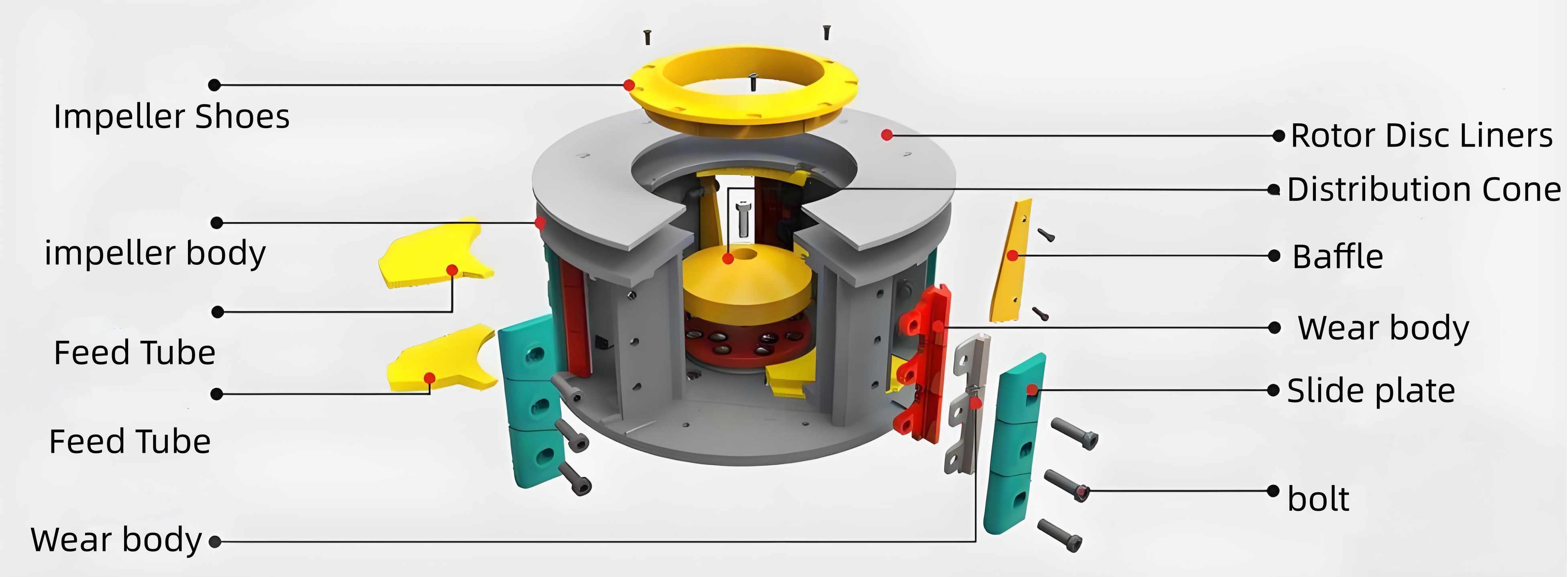

We manufacture vertical shaft impact(VSI) crusher rotor assembly components, including the rotor body, feed tube, feed ring, rotor disc liner, rotor shaft,baffle,wear blocks, bolts, distributor cone, and other wear-resistant parts.

We specialize in rotor production that integrates advanced materials, precision engineering, and strict quality control. Our VSI crusher rotors are constructed from high-quality, high-manganese steel, offering excellent wear resistance and toughness, making them ideally suited to withstand the intense wear and impact forces generated during the crushing process.