Global Sales OEM tailor design

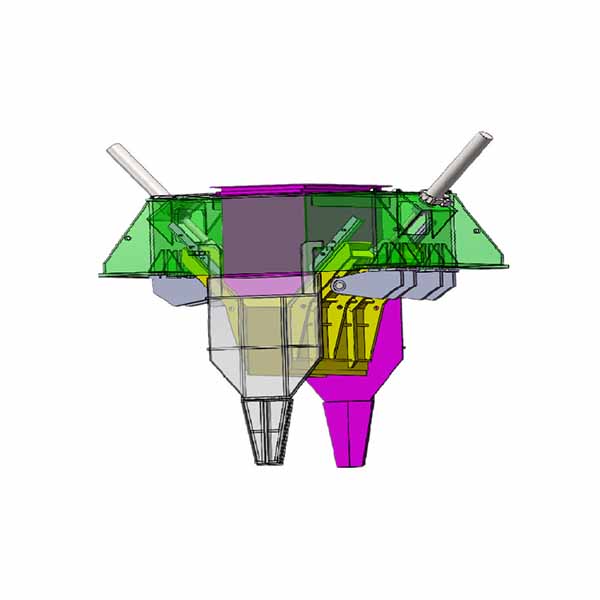

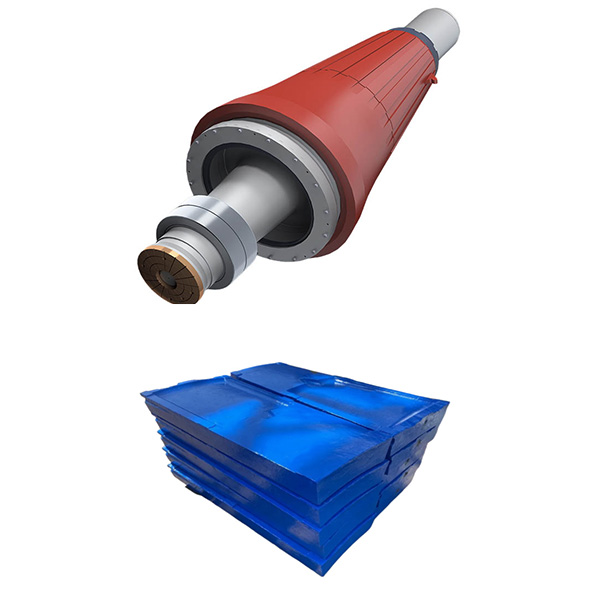

Product name: Hydraulic double slide feed device

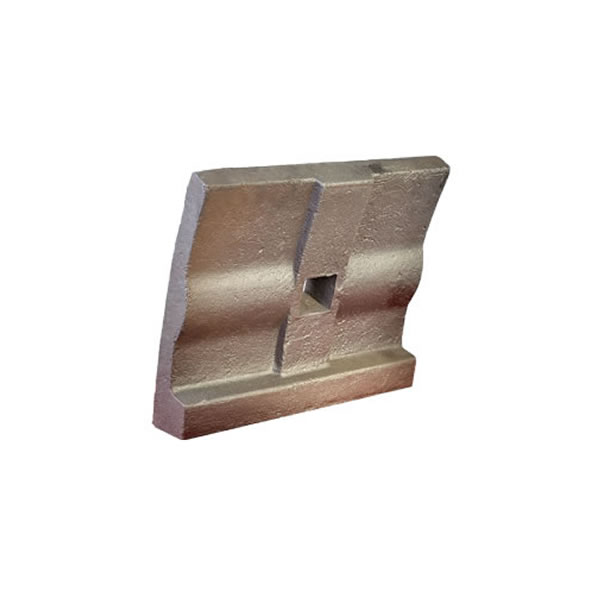

Production process: casting

Applicable industries: Cement, metallurgy, chemical industry, steel, pellets, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(cnwearparts@lyzhili.com), because we are a custom factory for wear-resistant castings.

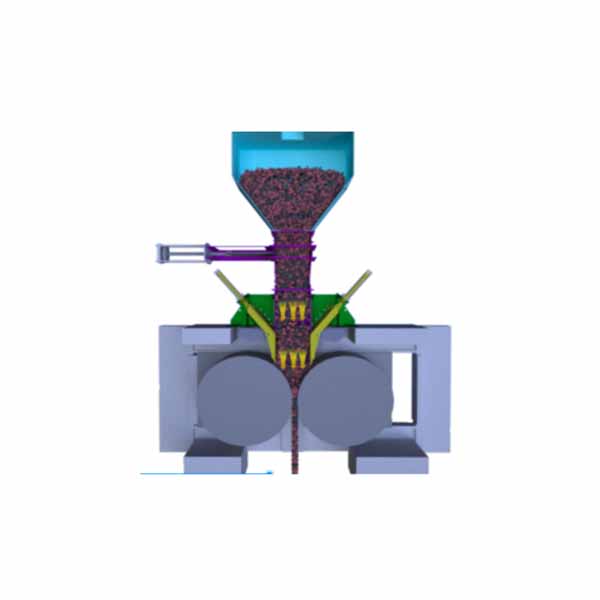

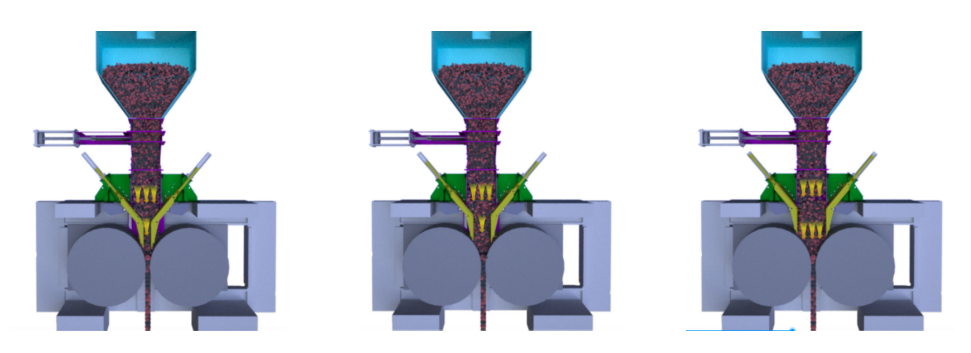

The hydraulic double slide rail feeder is developed based on the design and use experience of roller presses and the field use characteristics of the previous generations of roller press feeders. It has many advantages such as full roller width operation, precise and adjustable material throughput, and extremely low failure rate. It is the most advanced roller press feeder product on the market.

During the entire opening and closing process of the hydraulic double slide rail feeder, the bottom of the flow regulating plate can always move close to the roller surface. In addition to accurately adjusting the thickness of the material column and effectively limiting the material from forming a closed extrusion cavity, it can also make the material pressure in the silo always act between the two rollers, which is more conducive to the effective work of the roller press.

Eight advantages of the hydraulic double slide rail feeding device:

1. Full roller width working design, the same specification roller press can achieve a larger effective working roller width, improve the extrusion efficiency of the roller press, and improve the problem of uneven wear of the roller surface.

2. The flow regulating plate, roller side baffle and side baffle always form a basically closed cavity, and the material is in a completely restricted state. A stable material column can be formed between the two rollers, so that the material fed between the two rollers is always in an oversaturated feeding state.

3. Regardless of the size of the opening, the material pressure in the weighing bin can always act between the two rollers, which is more conducive to the work of the roller press.

4. The unique design of the side baffle ensures that the gap error of the side baffle can be accurate to about 1mm, greatly reducing the amount of material leakage at the edge of the roller,

reducing the system power consumption caused by ineffective circulation.

5. The side baffle and the end face of the roller can be kept parallel to protect the end face of the roller from abnormal wear.

6. The side baffle is designed with a quick replacement structure, and the side baffle can be replaced in 30 minutes.

7. Good sealing solves the dust leakage problem of the old feeding device and effectively improves the on-site environment.

8. The independent hydraulic system of the feeding device has accurate and reliable hydraulic transmission, the opening and closing speed of the flow regulating plate is adjustable, and it is maintenance-free on a daily basis, which solves the problem of equipment damage caused by dust accumulation and jamming of the screw drive.

The hydraulic double-slide feeding device has been widely used in cement group companies such as Zhonglian Group, Qilianshan Group, and Shanshui Group. Based on the technological leadership of the product, the hydraulic double-slide feeding device has become the preferred product for more and more customers to improve the technical transformation of roller press feeding devices.