Global Sales OEM tailor design

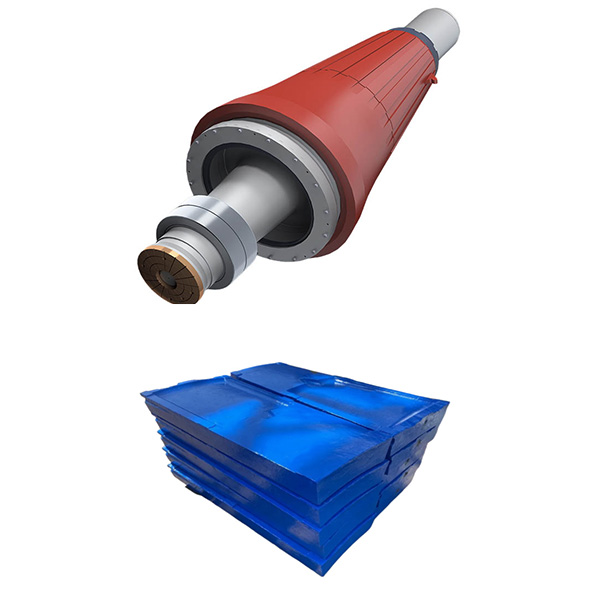

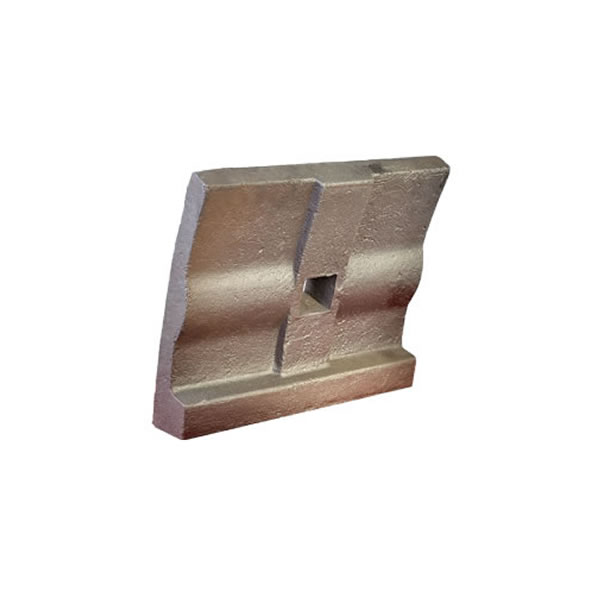

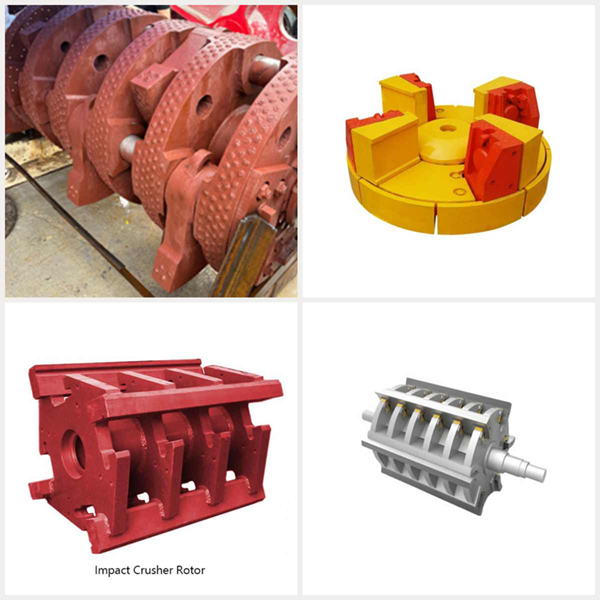

Product name: Clinker Crusher Hammer

Production process: Casting

Applicable machines: Clinker crusher

Applicable materials: Clinker

Material types: High manganese steel, high manganese steel inserd alloy bars, high manganese steel + hard facing layer, bimetal composite, high chromium cast iron, alloy steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(cnwearparts@lyzhili.com), because we are a customized factory for crusher spare parts.