Global Sales OEM tailor design

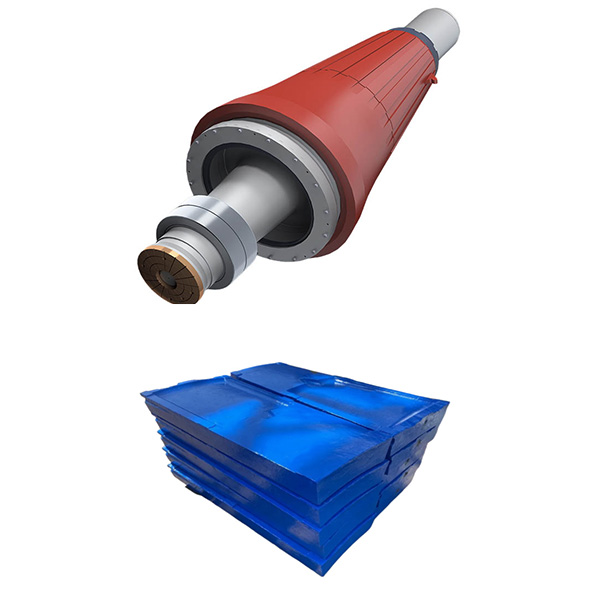

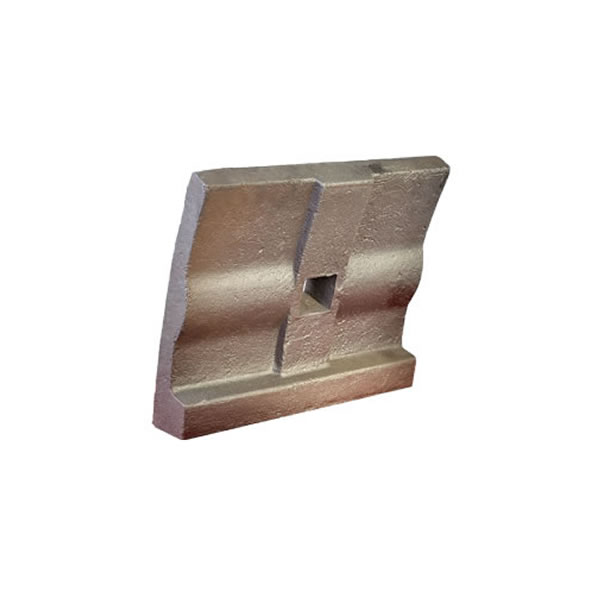

Product name: Grate Cooler Cover Plates/Heat-resistant steel Cover Plates/Sealing cover

Production process: Casting, Lost foam casting,V method casting

Material types: ZG40Cr28Ni20,12Cr1MoV,25Cr2MoVA,12Cr2MoWVTiB,Low-alloy heat-resistant steel, low-chromium-nickel oxidation-resistant steel,etc.

Applicable industries: Cement, metallurgy, chemical industry, architecture,steel, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(cnwearparts@lyzhili.com), because we are a customized factory for heat-resistant steel castings.

The sealing cover plate of the grate cooler has a U-shaped structure. The top surfaces of the two grate plates are fixed with spacers corresponding to the grooves of the sealing cover plate. The two side plates of the sealing cover plate are respectively placed on the two grate plates. The bottom surface of the side plate fits with the top surface of the grate plate to form a plane friction seal, and the spacers are embedded in the corresponding grooves.

The sealing cover plate mainly plays the following roles:

(1) Protect the drive plate;

(2) Lock the wind, that is, avoid or reduce the wind leakage from the wind chamber from the process gap;

(3) Prevent the material on the grate plate from falling into the wind chamber from the process gap and causing wear of other parts.