Global Sales OEM tailor design

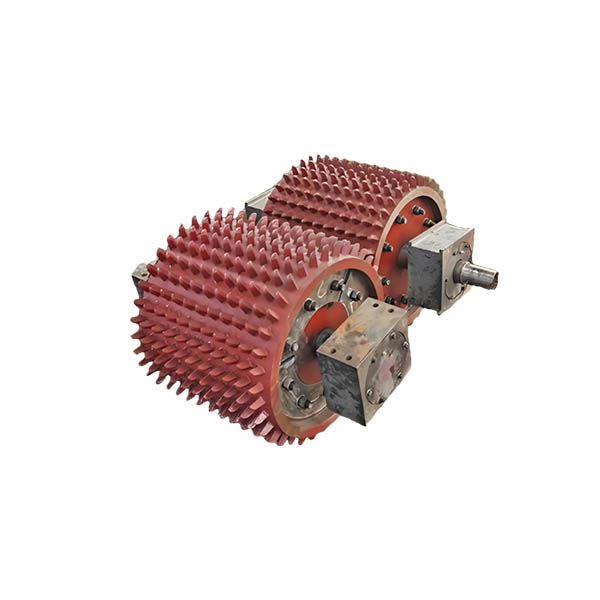

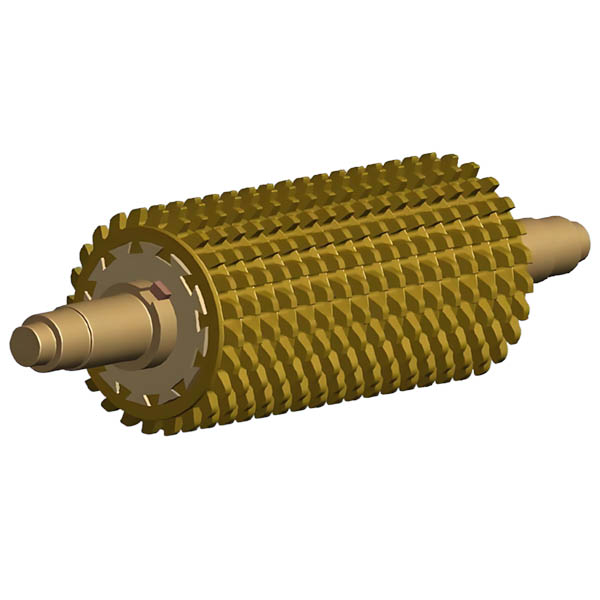

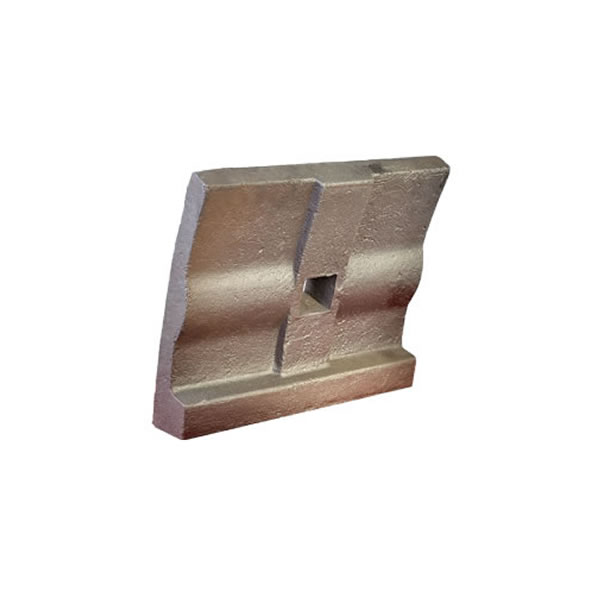

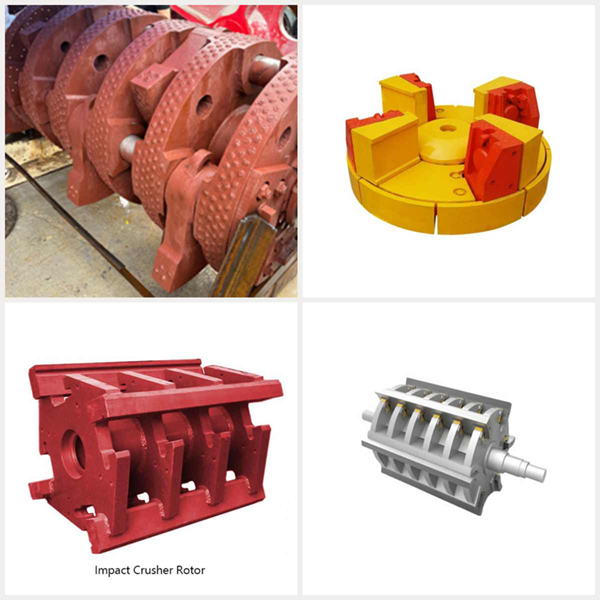

Product name: Crusher Toothed Roller,Toothed Roll,Crusher Roller,Roll Shell,Roll Sleeve

Production process: Casting

Applicable machines: Double Toothed Roll Crusher,Single tooth roller crusher,Four-tooth roller crusher,Classifying crusher,etc.

Applicable industries: Cement, stone,mining,coal,steel,metal recycling,power, etc.

Adaptable materials: granite, basalt, limestone, metal mines, river pebbles,slag, glass, etc.

Material types: High manganese steel, alloy steel, high chromium cast iron, bimetallic composite, etc.

Our service:

1. Before sales, we will fully understand the customer's working conditions and recommend the most appropriate material selection to the customer.

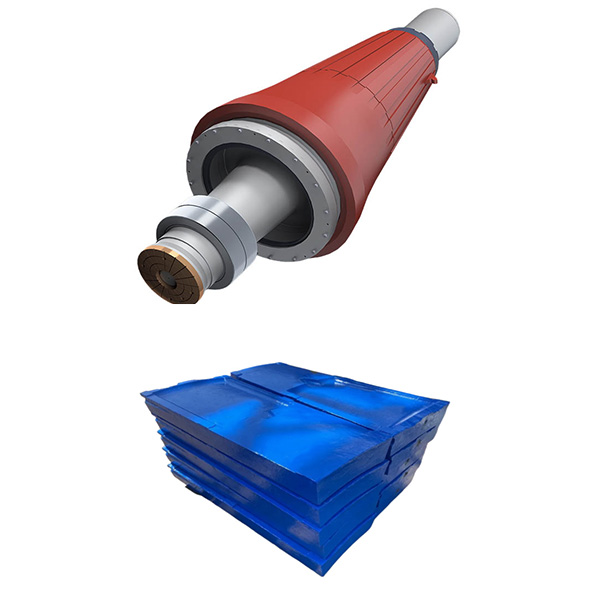

2. Provide customers with drawings based on their machine models, spare parts dimensions, etc.

3. After sales, we will continue to pay attention to the usage of the product and provide timely help.

4. Ensure that the quality of the purchased components is impeccable, and the technical parameters absolutely meet national standards.

5. Provide free quotation, worldwide sales, short delivery cycle, low price.

If you need detailed technical information of the product or cannot find the product you need on the website, please email us(cnwearparts@lyzhili.com), because we are a customized factory for crusher spare parts.

Recommended materials for wear resistance:

High manganese steel: A traditional material that hardens and becomes wear-resistant under strong impact.

Alloy steel: Such as 42CrMo, offers excellent comprehensive mechanical properties.

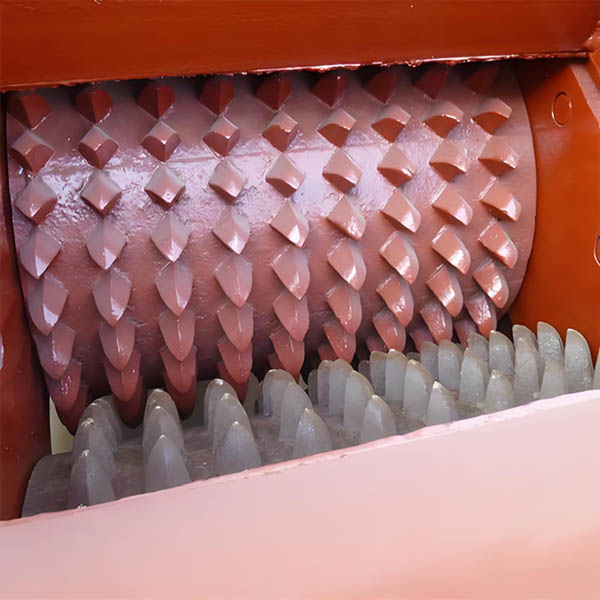

High-chromium cast iron/bimetallic composite: The current mainstream high-end choice. The teeth are made of highly wear-resistant high-chromium cast iron, while the roller core is made of high-toughness carbon steel. This composite casting process results in a lifespan 2-3 times that of traditional materials.

Advanced Manufacturing Process

Diverse tooth profiles: Spike, knife, corrugated, and customizable.

Overlay technology: When manufacturing new rollers or repairing old ones, extremely hard alloys such as tungsten carbide can be applied to the surface, significantly improving wear resistance.

Heat treatment technology: Through processes such as quenching and tempering, the hardness and toughness of the roller surface and core are optimized.

Sleeve/gear ring design: The gear roller is no longer a single unit. Instead, a sleeve or ring made of highly wear-resistant alloy steel is mounted on a tough carbon steel roller core.