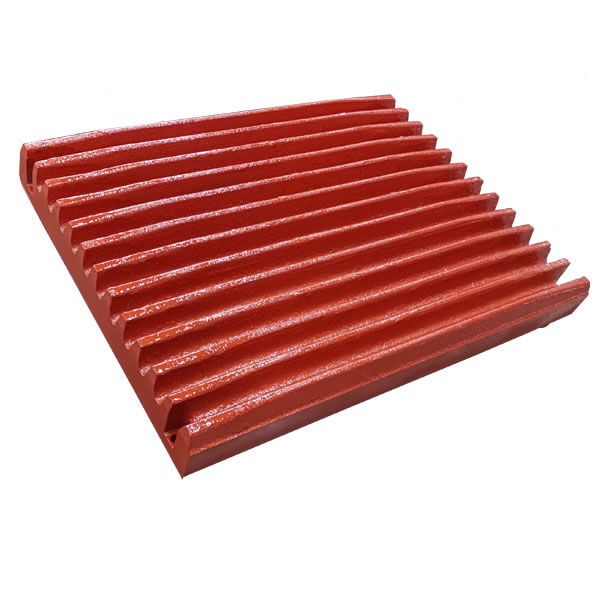

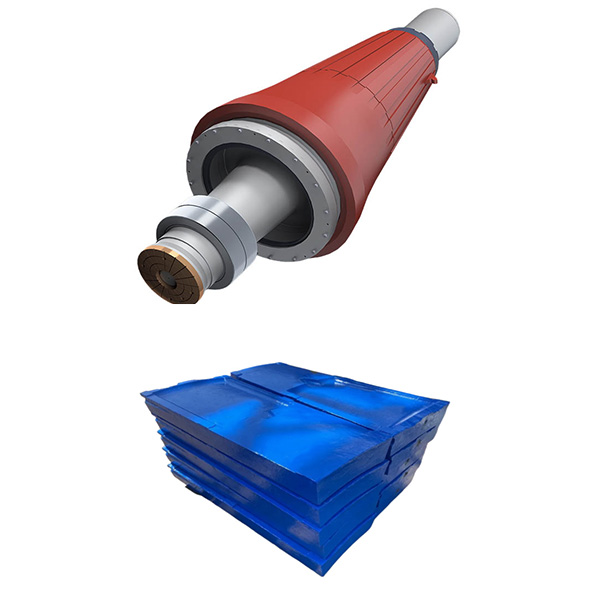

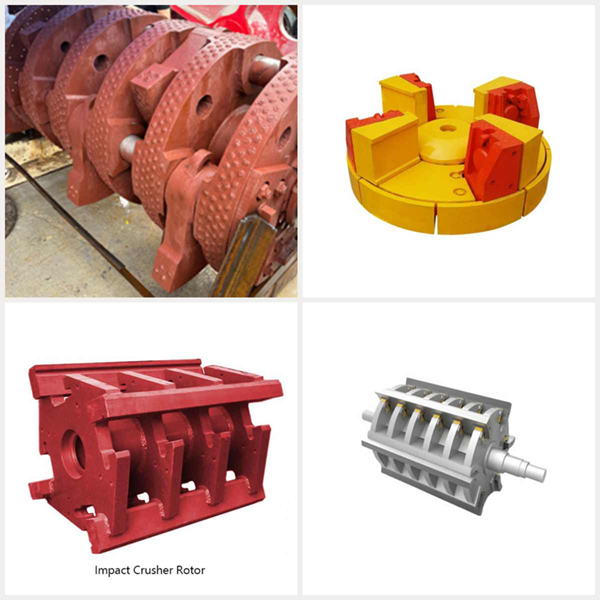

Ball mill lining is an important accessory for protecting the inner wall of the mill. It has the functions of improving grinding effect, production efficiency and extending the service life of the mill. There are many materials for mill linings. You can choose linings of different materials according to the working conditions of the working part. We are committed to producing linings of various shapes and different materials of new materials, which can help you choose.

The main materials of the mill linings we produce are:

High manganese steel: It has good toughness and work hardening ability. When it is impacted and worn, the surface will harden rapidly, thereby improving wear resistance. It is widely used in various types of ball mills, especially ball mills that process ores with medium hardness or below, such as iron ore, copper ore, etc.

High chromium cast iron: It has high hardness, good wear resistance, and certain corrosion resistance. It is suitable for processing materials with higher hardness, such as quartz stone, granite, etc. However, the toughness of high chromium cast iron is relatively poor and it is prone to brittle fracture.

Medium manganese ductile iron: The manganese content is 7%-9%, the silicon content is 3.4%-4%, and the carbon content is 3.2%-3.6%. Its service life is not less than that of high manganese steel, but its cost is much lower, which has a good cost performance ratio.

Magnetic lining: It uses magnetism to absorb steel balls and magnetic materials to form a self-protective wear-resistant layer, thereby reducing the direct wear of the lining. It has the advantages of long service life, easy installation and maintenance, reduced mill operation load, and reduced noise, and is suitable for ball mills of various specifications.

Rubber: It has good elasticity and shock absorption performance, which can reduce the impact of steel balls on the lining, and reduce the vibration and noise of the equipment. It is suitable for occasions where high material grinding precision is required and equipment wear and noise are reduced, such as the fine grinding bin of cement mills and the grinding of ceramic raw materials.

Polyurethane: It has high strength and elasticity, good wear resistance, and good corrosion resistance and anti-aging performance. It is suitable for some ball mills with high environmental requirements and strong material corrosion, such as grinding of certain materials in the chemical industry.

High aluminum ceramics: It has good wear resistance, impact resistance and corrosion resistance. It is widely used in the inner wall lining of ore crushing and grinding equipment, which can effectively resist the impact and wear of abrasive particles on the inner wall.

Silicon carbide ceramics: high hardness, good wear resistance, excellent thermal conductivity, and can withstand high temperature and acid-base corrosion. Suitable for high-speed ball mills and occasions with high requirements for abrasive particles; in the steel industry, it can be used for the lining of large blast furnaces to improve the working efficiency and product quality of ball mills.

Zirconia ceramics: used in ore crushing and grinding equipment, it has high hardness, wear resistance and corrosion resistance, as well as good thermal conductivity and insulation properties. Suitable for processing high-hardness, high-abrasiveness and high-viscosity abrasives, such as aluminum smelting furnaces, copper smelting furnaces, etc., which can effectively extend the service life of ball mills.

Rubber composite magnetic lining: Combining the elasticity of rubber and the self-protection function of magnetic lining, it has good shock absorption effect and can effectively reduce the wear of lining. For example, the drum surface of magnetic separators in the metallurgical industry and the lining of material conveying pipelines use rubber composite magnetic linings to improve service life.

Metal composite magnetic lining: With metal as the base, a layer of magnetic material is composited on the surface. It combines the strength of metal and the self-protection performance of magnetic materials, has high wear resistance and reliability, and is used in coal mills in thermal power plants to absorb ferromagnetic impurities in coal, form protection, and reduce lining wear.

The above are various materials for linings. You can make reasonable choices according to your working conditions. If you need to customize special working conditions, you can find Zhili New Materials Company. We have rich technology and construction experience and can help you choose the most suitable lining to increase machine production capacity.