Luoyang Zhili New Materials Co., Ltd. was established in 1992 as one of the world's leading wear-resistant material processing centers. It has long provided high-quality wear-resistant components and services to industries such as mining, cement, power plants, steel, and coal. In 2017, to better expand into the global market, the company established Zhili International Limited in Hong Kong, China, dedicated to offering reliable wear-resistant solutions to customers worldwide.

The company operates a modern factory covering 18,000 square meters, equipped with a complete range of advanced production facilities. The smelting process utilizes medium-frequency induction furnaces exclusively, including multiple 5-ton, 3-ton, 2-ton, and 1-ton models. It has established several advanced production lines incorporating various processes such as resin sand, lost foam, and iron sand lamination, along with three high-efficiency welding robots, achieving an annual total production capacity of 8,000 tons. Through advanced techniques like argon refining, composite material embedding, additive overlay welding, and isothermal heat treatment, the company ensures stable and excellent product performance. Additionally, a comprehensive machining and inspection system provides full-process quality assurance.

The company boasts a highly skilled team of technical experts, including several senior engineers, engineers, and assistant engineers specializing in material research and development, process design, production optimization, and other fields. They continuously provide reliable technical support and solutions to customers. Moreover, the team is well-educated, comprising professionals with master's, bachelor's, and associate degrees, collectively ensuring forward-looking and stable R&D and production capabilities.

With solid technical expertise, stable production capacity, and efficient delivery capabilities, we are committed to providing reliable wear-resistant solutions to global customers and look forward to becoming your long-term partner for mutual success.

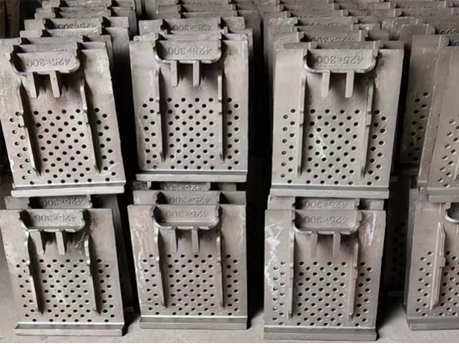

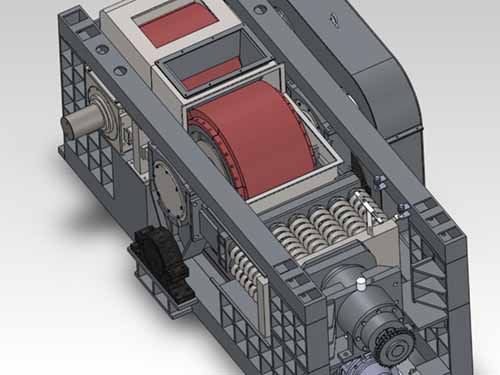

Wear-resistant equipment accessories

Jaw crusher spare parts

Ball mill spare parts

Cone crusher spare parts

Impact crusher spare parts

Vertical mill spare parts

hammer crusher spare parts

Heat resistant steel

Roller Press Parts

By means of our unique knowledge and innovative solutions, we help our customers improve wear-resistance efficiency, reduce the risk of use, and help our customers save a lot of money, which is deeply loved by customers.

✔ China's first domestic manufacturer of bimetal composite hammers.

✔ Cooperating with several famous domestic large-scale cement manufacturers (Conch Cement, Taiwan Cement Corporation, Esheng group, etc.).

✔ Establish long cooperation with Posco, Cemex.

✔ In 2011, we have the honor to win “China top cement industry suppliers”.

✔ Our company win the honore of The third China Wear-resistant Material ”Golden globe”.

✔ In 2013, we cooperated with the world first cement group Lafarge.

✔ We established long time cooperation with Mexican Cement Group Cemex.

✔ In 2017, in the sharp competition, the company successfully obtained the official authorization of HARDAX wear-resistant steel plate from SSAB and became the Hardox Wear Product Service Center.

✔ 2018 Reached cooperation agreements with several Middle Eastern cement plants.

✔ 2019 In order to expand production, shorten delivery time, and meet the order needs of domestic and foreign customers, the company established a branch factory in Yunnan and set up a new company.

✔ 2020 The ceramic metal composite series products developed by the company were successfully launched.

✔ 2023 We independently developed a heat resistant and wear-resistant technology - ceramic composite matrix reinforcement technology.

✔ 2024 After strict review by the international certification body GICG, the company successfully passed the ISO quality management system certification and obtained the certification certificate.

overview of factory equipments

welding robot

detection device

Laser cutting equipment

Machining equipment

Machining equipment