1、Performance characteristics of the ceramic metal composite vertical mill roller/table liners developed by our company

Safe and reliable structure

The ceramic metal composite roller sleeve is composed of a wear-resistant strip composed of ceramic and high chromium alloy and a high-toughness ductile iron base material. The unique structure has the characteristics of wear resistance and stability

Better wear resistance

The wear-resistant strip is compounded with high-hardness ceramic, which increases the wear resistance by 2-3 times, and the wear is even, which can keep the original appearance of the wear parts for a long time, and the operation stability is higher

High grinding efficiency

After the wear-resistant parts are worn, a ceramic metal honeycomb structure is formed on the surface, which increases the surface and material grinding area and bite force, and improves the grinding efficiency

Personalized solution design

According to the customer's wear conditions, the wear-prone area is enhanced and the wear line is more reasonable

High economic benefits

Long service life, high stability, reduce production losses caused by downtime replacement or repair, reduce maintenance costs, and have stronger maintenance planning

Material saving and environmental protection

Avoid harmful gases generated during the surfacing process of alloy roller sleeve linings, while reducing the use of steel and reducing carbon dioxide emissions

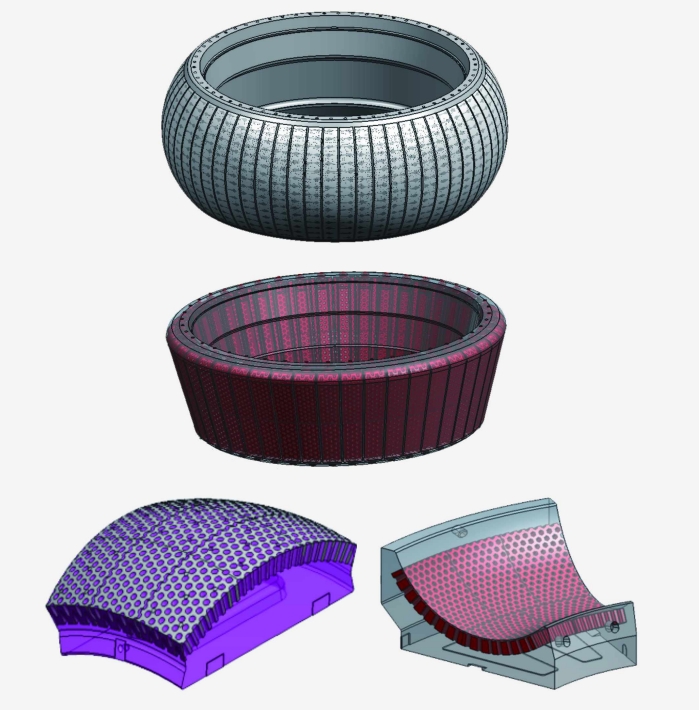

2、Performance characteristics and structural diagram of ceramic-metal composite vertical mill roller/grinding table liner

3、Application cases of ceramic metal composite vertical mill roller/grinding table liner

RM51/26 Raw Material Vertical Mill for a Cement Company

Material | Date of commissioning | Date of inspection | Elapsed time (h) | Maximum wear depth(mm) | Average wear depth(mm) | Output per hour(t/h) |

High chromium cast iron | Late January 2018 | Early May 2018 | 1840 | 32 | 17 | 380 |

Hardfacing composite | Late January 2018 | Early May 2018 | 1840 | 32 | 18 | 380 |

Ceramic metal composite | Late May 2020 | Early May 2021 | 8110 | 36 | 28 | 397 |

High chromium cast iron grinding roller Hardfacing grinding roller Ceramic metal composite grinding roller