In this hot summer, the European Cup is in full swing. Now we are entering a critical period. I hope that all players will perform exceptionally and achieve a good ranking. Today, I will introduce a grate cooler product to you to calm your restless mood.

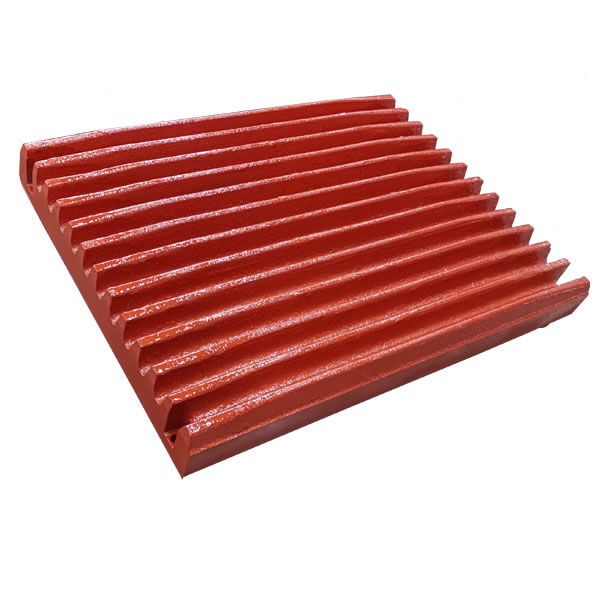

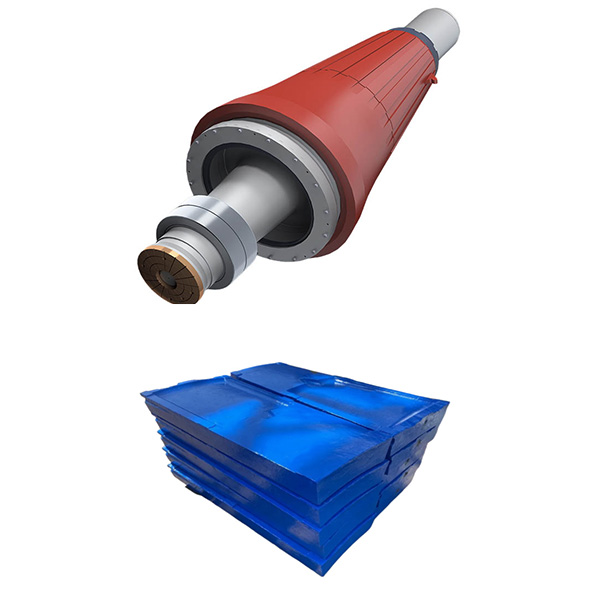

Grate cooler is an important equipment in the clinker burning system of cement plants. Its main function is to cool, recover heat and transport cement clinker. At the same time, it provides hot air for rotary kilns and decomposition furnaces, and is the main equipment for heat recovery in the burning system. Grate plate is an important component of the grate cooler. After the clinker enters the cooler from the kiln, it is spread in layers on the grate plate. Under the push of the grate plate, it moves forward while rolling to varying degrees. The cold air blown in passes through the moving material layer on the grate bed in a mutually perpendicular direction to cool the clinker suddenly, and the clinker can be cooled from 1300-1400℃ to below 100℃ in a few minutes. In the process of word, the grate plate material is required to have certain heat resistance, thermal stability at high temperature and sufficient wear resistance, and small deformation when the temperature fluctuates. The normal service life of the grate plate is more than 6 months. Our company has developed a new set of technologies. The service life of the grate plate made of heat-resistant steel material is twice that of the ordinary grate plate, which is well received in the industry. It extends the service life of the machine, increases production capacity, and saves costs for the enterprise.

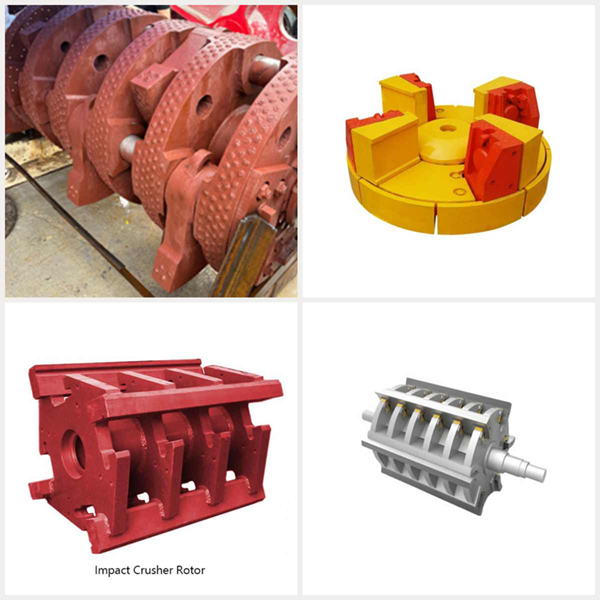

We also produce other heat-resistant steel castings, mainly preheater hanging plates, kiln tail guard plates, screen plates, etc. Interested friends can click on the online communication tool to communicate, or leave a message at the bottom of the page, and we will reply as soon as possible.