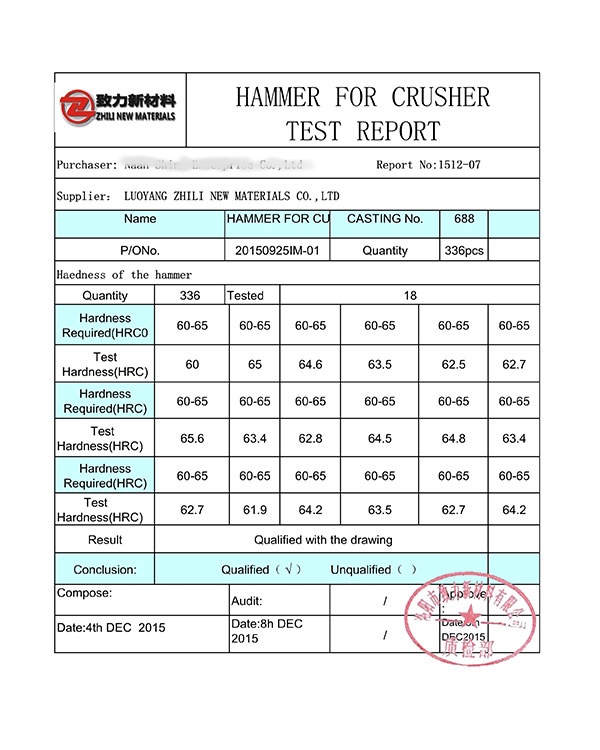

Quality test report

Quality is the most vital part of our production. 1% mistake from us will result in 100% disaster of our clients. We take advantage of any possible chance to increase our quality.

We conduct product quality inspections for each production process and form a quality inspection report.

After production, we will put multiple tests on our products to make sure that our products are much better than what’s “acceptable”.

The contents of the quality test:

● Chemical Component Analysis(Raw materials/accessories analysis, casting process analysis, the material of the finished goods test)

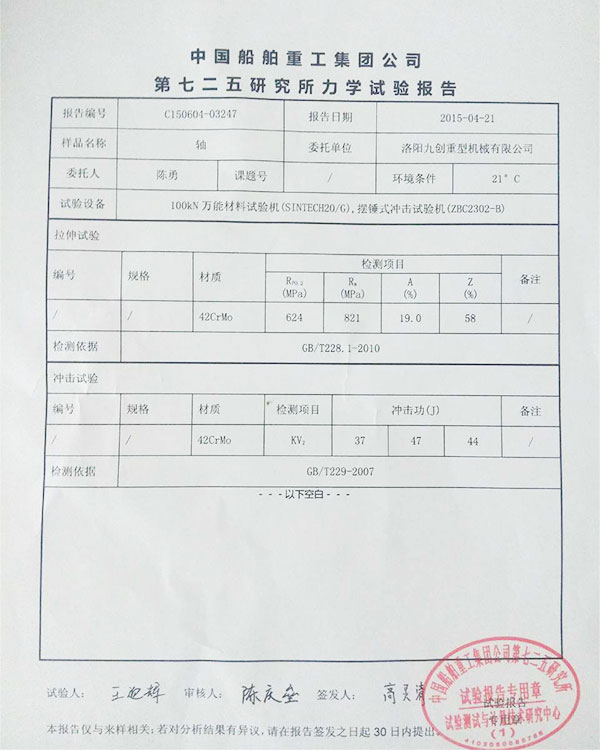

● Mechanical property test.

● Metallographic structure of the goods analysis.

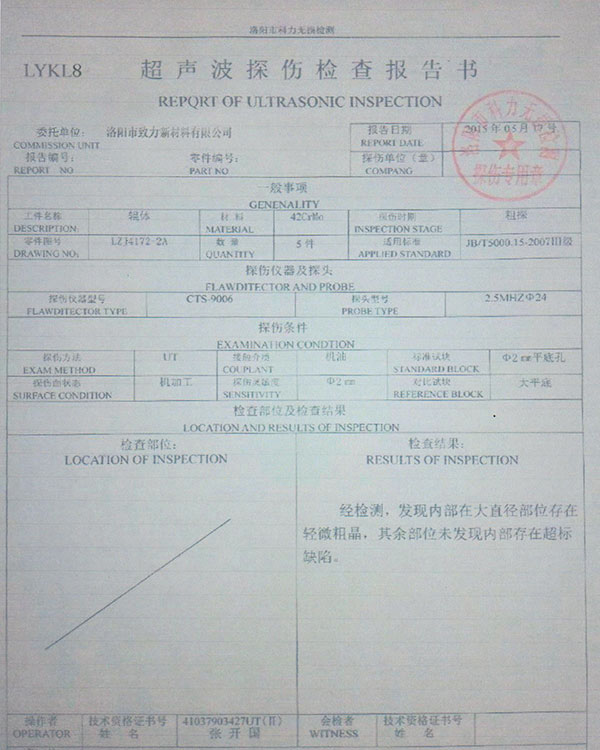

● Defect inspection of the goods(magnetic powder inspection, liquid penetrant examination, Ultrasonic wave examination, X ray flaw detection)

● According to the examination of the report, we make suggestion to our factory to improve our production process. We can provide failure analysis and give effective suggestion to customers. We can also provide authoritative report from the third part.

We can provide the reports according to customer’s demands. (Customers will pay the extra fee)

Anything you concerned about the quality system, please feel free to contact us , it will be our honor to work for you.

Component analyze report

We will make sure the components of our products perfectly fits our clients’ requirement.

● We use spectroanalysis instrument and do 2 examinations before pouring and after pouring.

● For each examinations we will do 5~6 tests repeatedly to get the most precise result.

● All casting parts have their own sample and report and they were kept for at least 3 years.

● If you need such report, we will definitely send it immediately.

Testing Equipment

The company has established a perfect quality management system, a reasonable organization and a clear division of responsibilities. The quality department independently performs the quality management duties and the company has passed ISO9000 quality management system certification.

The company adopts systematic, scientific and strict quality management methods and take advantage of advanced equipment to supervise the company's product quality.

Our company quality test equipment:

✔ Hardness instrument

✔ Ultrasonic wave defectoscope

✔ Spectrum analyzer

✔ etallographic structure analyzer

✔ 3D scanner

✔ Magnetic particle tester

✔ Pendulum impact testing machine

✔ Tensile testing machine

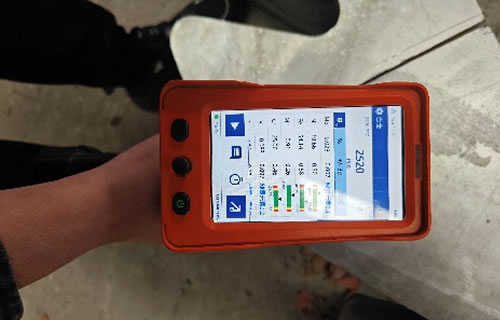

✔ Portable spectrometer

Spectrum analyzer

Spectrum analyzer

Metallographic microscope

Metallographic microscope

Pendulum impact testing machine

Pendulum impact testing machine

Tensile testing machine

Tensile testing machine

Benchtop hardness tester

Benchtop hardness tester

3D scanner

3D scanner

Ultrasonic flaw detector

Ultrasonic flaw detector

Magnetic particle tester

Magnetic particle tester

Portable spectrometer

Portable spectrometer

Test Report