There are many processes for Zhili New Materials to produce castings, including sand casting, lost foam casting, metal mold casting, pressure casting, centrifugal casting, etc. Lost foam casting is the most common way to produce castings. This process has many advantages, low cost, and many customers choose it.

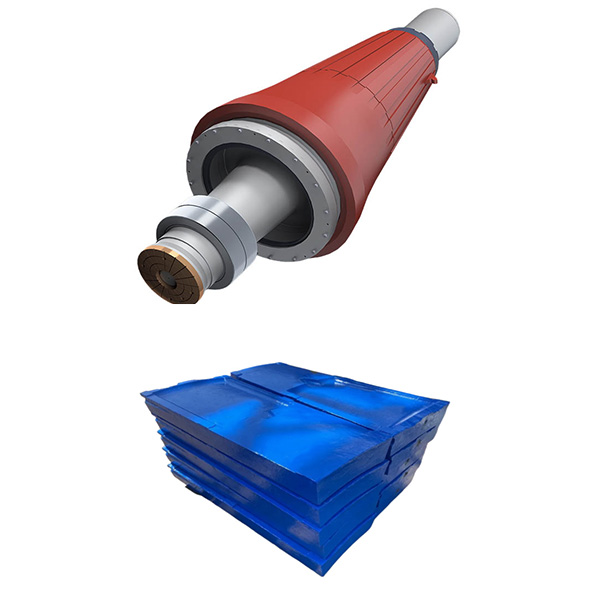

Lost foam casting refers to the use of foam plastic molds instead of traditional wooden molds or metal molds. Foam plastic molds are generally made of expandable polystyrene (EPS), expandable polymethyl methacrylate (EPMMA) or their copolymers. During the pouring process, the high-temperature molten metal causes the foam plastic mold to vaporize and disappear rapidly. The molten metal replaces the original foam plastic mold and forms a casting after cooling and solidification. After the casting is cooled to a certain temperature, pour out the dry sand in the sand box, take out the casting, and then clean the casting to remove the sand, burrs and pouring risers on the surface to obtain the final casting product.

Compared with castings produced by traditional processes, castings produced by lost foam casting process have many quality advantages in terms of dimensional accuracy, surface quality, internal defects, mechanical properties, etc., and have the following advantages: no need for traditional modeling processes such as demolding, core setting, and box closing, which greatly simplifies the casting process, improves production efficiency, and reduces labor intensity. At the same time, since the mold is integrally formed without parting surfaces and cores, the casting has high dimensional accuracy and good surface quality, which can reduce machining allowances and reduce production costs.

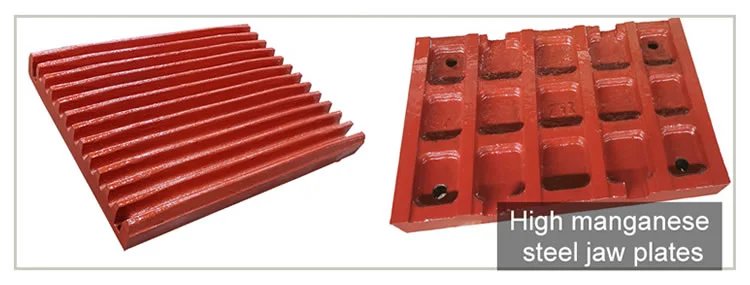

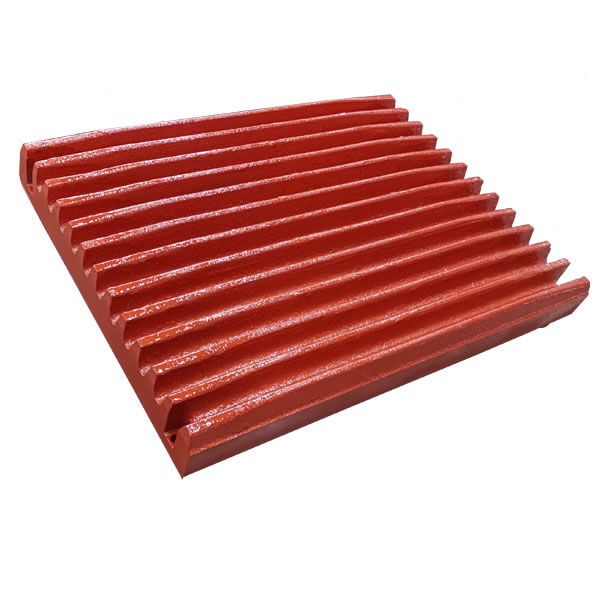

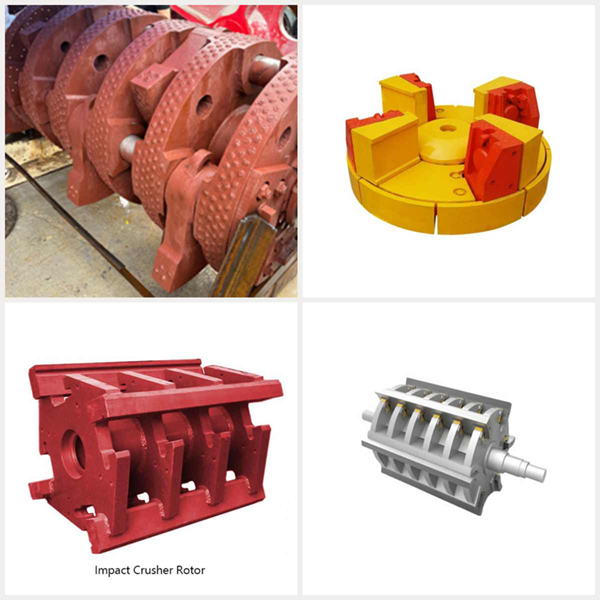

Lost foam casting is suitable for the production of castings of various metal materials, including high manganese steel, high chromium cast iron, cast steel, aluminum alloy, copper alloy, etc. It is widely used in large crushers, mills, machinery manufacturing, agricultural machinery, pipe fittings and other industries, and can produce castings of various complex shapes, such as crusher jaw plates, hammers, crusher rotor bodies, engine cylinders, cylinder heads, crankcases, gearboxes, valves, pipe fittings, etc. We have rich experience in the production of lost foam castings. If you need it, you can contact us actively. We provide free design and quotation.